- Mark-9 -

Reliable, Lightweight, High-tech Propeller Reduction Gearbox

NOTE: All our Products, Designs, and Services are SUSTAINABLE, ORGANIC, GLUTEN-FREE, CONTAIN NO GMO's, and will not upset anyone's precious FEELINGS or delicate SENSIBILITIES.

In September of 2012, a special version of the Mark-9 PSRU competed in the Reno Air Races Gold Sport Class in Lee Behel's GP-5, named Sweet Dreams. This racer was powered by an excellent, ECU-controlled, 625 HP V8 engine built by Paul Hasselgren. It qualified at 363 mph, finished third in two of the heat races and finished fourth (359.6 mph) in the Sport-Gold race. For a detailed description of this gorgeous, successful V8-powered race airplane, CLICK HERE.

The picture below shows a cutaway example of the Mark-9. This cutaway was made for airshow displays, and was seen at Sun n' Fun and AirVenture in the EngineAir displays. To see pictures of that display, as well as some higher-quality pictures of the Mark-9 and some of the aircraft on which it has flown, CLICK HERE )

Following the 2012 Reno Air Races, there has been a renewed interest in the Mark-9. That has provided the stimulus for us to start a new design effort which will make the Mark-9 available again soon, with updated CNC-from-Billet housings in place of the original castings, with the new idler bearing system, with a wider range of ratios and engine adapters, improving the light, reliable compact Mark-9 gearbox even more.

The EPI Mark-9 PSRU was first used in the EngineAir Power Systems 440 HP liquid-cooled V8 powerplant. That engine system was installed in the Lancair 4P which won the Kittyhawk-to-Oshkosh Race in 1999 (and which would have won in 2000 and 2001 if the pilot hadn't gotten lost).

The Mark-9 was also in the Lancair-4P which won Grand Champion at Sun n' Fun 2001, in Doug Pohl's Lancair 4P, which made it's first flight on July 9, 2001,as well as in Tom Hakes' Lancair 4P which made it's first flight in late 2001, in in Gary Wolf's Lancair-4P and Steve Ramsey's Lancair 4P, both of which made their first flights in Mid-2002.

The prototype of this design reportedly accumulated over 800 hours of in-flight time in Lancair-4P aircraft, including several races, countless full-power demonstration flights, and extended instances of being flown in hard-IFR (by a very brave pilot).

As of April, 2003, there had been more than 20 of these hgh-tech PSRU's installed in various aircraft, ranging from Lancair 4P's to a modified Beech Duke. Many of those installations have flown, and several have accumulated significant time in flight. (For anyone interested, The Long Story behind the development of the Mark-9 PSRU can be seen HERE.)

As of late 2005, several production versions had accumulated over 500 hours of problem-free flight time.

The EPI Mark-9 PSRU is a two-mesh (idler-type) reduction gearbox which allows the propeller to turn in the same direction as the engine. The propshaft has the high capacity ARP-880 8-bolt, 2-dowel flange (the same one used on the PT-6 and TPE-331 turbine engines). The Mark-9 thrust capacity is 2000 lbs. The vertical distance between the crankshaft and propshaft centerlines is 6.125 inches. The ratios available range from 1.63 to 2.63, in steps of about 0.05.

The gearbox includes a gear-drive (AND-20010) for a standard Woodward - Hartzell - Jihostroj prop governor, with fully internal plumbing for the prop control hydraulics and for lubrication, and an optional integrated 58-tooth crank trigger with dual sensors for the engine management computer. It uses pressure-fed engine oil for lubrication and cooling, and has an integrated scavenge pump to return oil to the engine sump.

The gears are straight-cut (spur) gears made from a specially heat-treated high-grade manganese-nickel-chrome-molybdenum alloy (E-9310), and finished to AGMA Quality 10 minimum. They have a face width of only 1.5 inches (in the model suitable for 600 LB-FT of engine torque). The gears have special design features which greatly improve their resistance to both hertzian and bending fatigue, as well as to prevent the edge-loadings which are so destructive to highly-loaded gears.

(For an expanded discussion of the advantages of Spur Gears, CLICK HERE)

The version of the Mark-9 PSRU which EngineAIR Power Systems used for their 440 HP LancAir-4P V8 engine package has a reduction ratio of 2.19, an input torque capacity of 600 lb-ft,, and weighs 73 lbs.

Other versions of this PSRU can accommodate up to 850 lb-ft. of input torque and can have ratios from 1.60 to 2.58. The weight varies with the torque capacity and the reduction ratio. The prototype weighed 71 pounds and had a ratio of 1.86, but has a lower torque capacity of 500 lb-ft.

EPI's proprietary system for coupling the engine to the PSRU attenuates over 99% of all engine torsional excitation and provides nearly turbine-smooth input to the PSRU. That provides an environment for the propeller which is free from torsional excitation.

FEATURES

Here is a summary of the Mark-9 features:

- The Mark-9 has provisions to fit these popular engines: Small Block and Big Block Chevy, GM-LS, Ford Windsor, Jaguar-V12, and other custom configurations as well.

- The vertical offset between the crankshaft centerline and the prop centerline is 6.125 inches;

- The available ratios range from 1.636 to 2.632 in steps of approximately 0.05

- Propeller rotation is in the same direction as engine rotation;

- The input torque capacity exceeds 850 lb-ft. (depending on the required safety-margin);

- The propeller thrust capacity (all configurations) is over 2000 lbs. in either direction (pusher or tractor applications);

- The propeller flange conforms to SAE ARP-880, which is the 8-bolt, 2-dowel configuration used on the P&W PT-6 and Garrett TPE-331 turbine engines, and most Continental GTSIO-520 engines;

- The minimum length from engine to prop flange is 13.9 inches. The Mark-9 is available with extended propshafts to move the propeller further away from the engine to assist with specific cowling issues;

- The integrated controllable propeller system is the common single-acting hydraulic configuration (Hartzell, McCauley, AeroComposite, MT, Hoffmann, etc.) found in most piston-engined aircraft. The propeller governor drive is integrated into the gearbox and provides an AND-20010 governor mounting pad, vibration-isolated gear-drive, and internal propeller control plumbing;

- The Mark-9 includes provisions for a reversing prop and the PT-6-style beta-feedback mechanism for the control of a reversing prop;

- The Mark-9 uses engine oil for lubrication, cooling and propeller control, so it requires no additional heat exchangers, which helps to reduce cooling drag;

- The Mark-9 contains several gearbox "health-monitoring" features, including (i) a chip detector, (ii) two temperature sensors (for incoming and exiting oil) and (iii) an oil pressure sensor location.

- The typical weight is approximately 71 pounds (NOTE: weight varies with ratio and torque capacity).

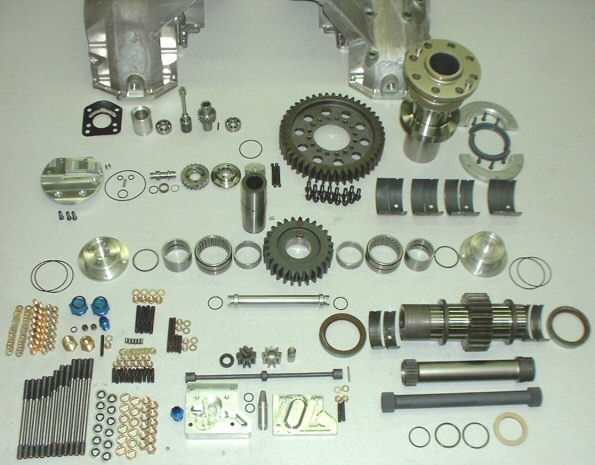

COMPONENTS

The picture below shows all the components that make up the Mark-9 Gearbox System.

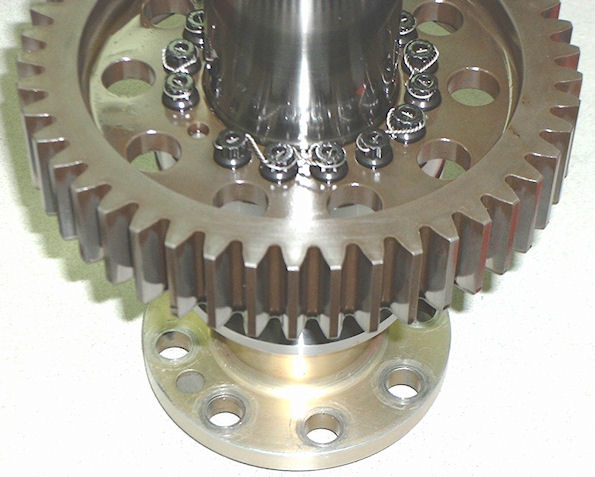

The picture below shows the output gear assembled to the propshaft in a Mark-9 Gearbox System.