FEA of the Factory 35mm Secondary Shaft

Secondary Shaft Tensile and Compressive Axial Stresses and Deflections

ProDrive Belt System Compared to the Factory Chain Drive.

NOTE: All our Products, Designs, and Services are SUSTAINABLE, ORGANIC, GLUTEN-FREE, CONTAIN NO GMO's, and will not upset anyone's precious FEELINGS or delicate SENSIBILITIES

The following FEA plots show the tensile and compressive axial stresses and the deflections in the Factory 35mm secondary shaft which result from the ProDrive belt system, as compared to those applied by the factory chain drive.

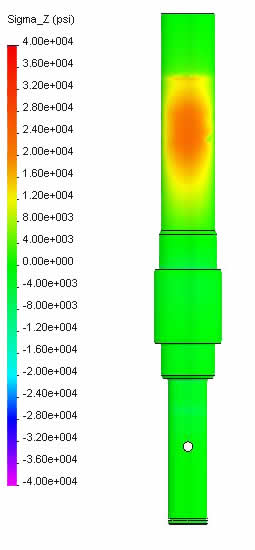

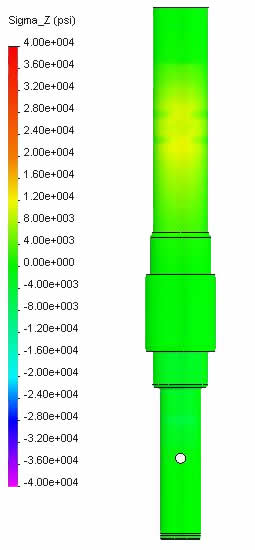

These plots show the tensile stresses in the 35mm shaft in the cruise condition. The tensile stress is on the side away from the main rotor shaft, and the distribution is greater below the bearing than above it. It is clear from these pictures that the tensile stress (which initiates fracture) is much lower in the chain drive system.

Tensile Stress |

Tensile Stress |

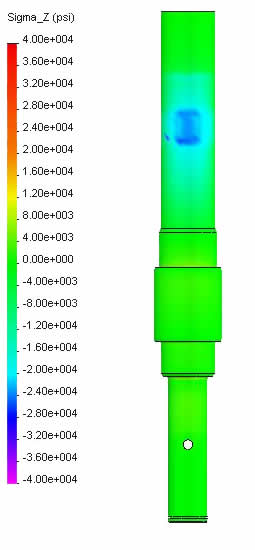

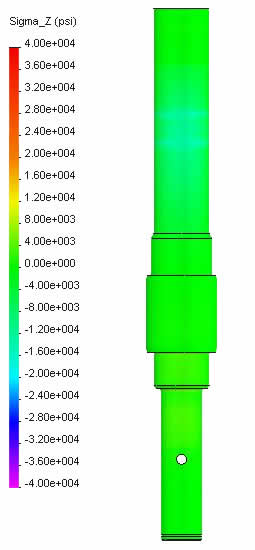

The next two plots show the compressive stresses in the 35mm shaft which result from the toothbelt drive and the factory chain drive system, in the cruise condition. It is clear that the compressive stress concentrations (which accelerate fretting) are much lower in the chain drive system. (The legend range is from +40,000 to -40,000 psi.)

The compressive stress plot shows the concentrations at the upper and lower edges of the bearing inner race. These concentrations, together with the larger deflections produced by the greater stresses, contribute to the higher rate of fretting.

Also, NOTE that this analysis was done WITHOUT the press-fit sleeve which goes below the bearing, so the compressive stress concentrations which the sleeve produces are not shown in these plots. Be secure, however, that they ARE there.

Compressive Stress |

Compressive Stress |

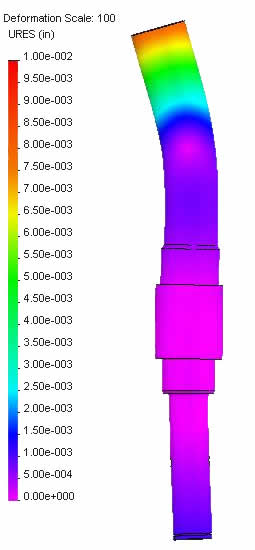

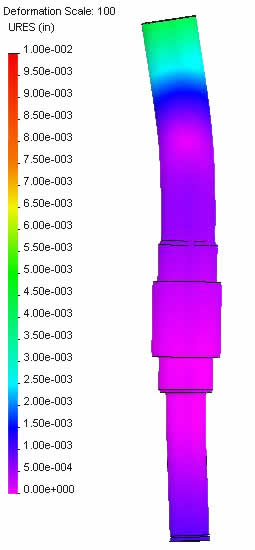

The plots below compare the shaft deflection (exaggerated up by a factor of 100 for visibility) caused by the toothbelt system (at any operating condition) and the chain drive in the cruise condition. (The legend range is from 0 to 0.010 inches.) It is clear from these pictures that the deflections at the shaft-bearing interface (which accelerate fretting) are much higher in the belt-drive system than in the chain system.

Deflection |

Deflection |